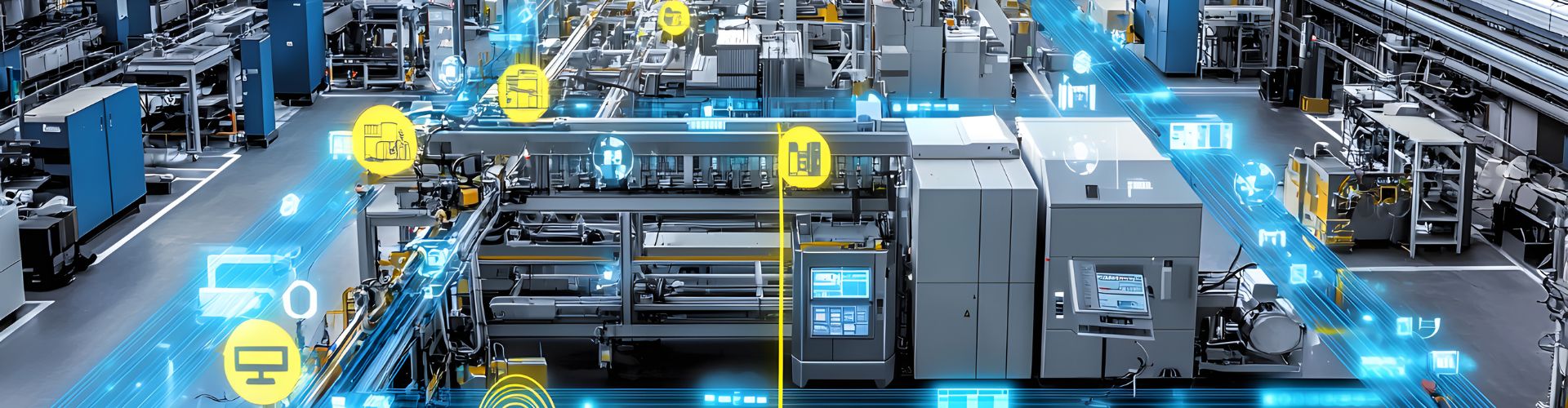

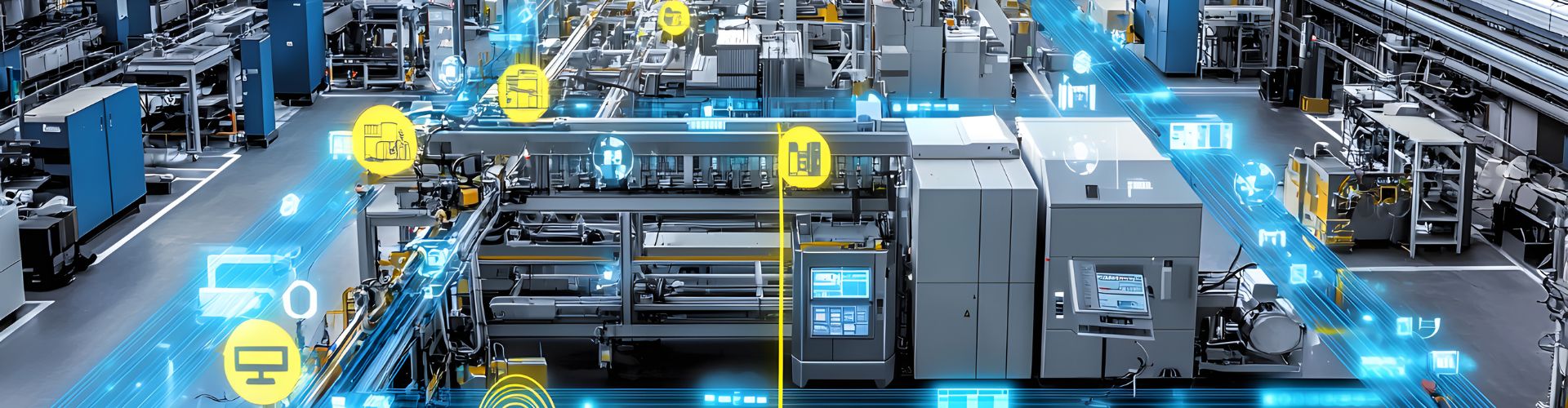

Manufacturing is evolving, and it’s happening fast! Gone are the days when factories relied solely on manual labour and simple machinery. Today, smart factories are taking the stage, blending advanced technologies like IoT, AI, and robotics to revolutionize the way things are made. These digital powerhouses are not just about efficiency—they’re about creating a connected and sustainable future for industries. But what exactly makes a factory “smart,” and why should it matter to us?

What Makes a Factory Smart?

Think of a smart factory as a brainy production line. It’s a place where machines, systems, and even people work together seamlessly using advanced technology. Imagine sensors tracking every step of production, AI analysing data in real-time, and robots taking care of repetitive tasks. The result? Faster, more efficient, and smarter manufacturing.

The Cool Tech Behind Smart Factories

- IoT (Internet of Things): IoT gadgets act like the eyes and ears of a factory, constantly gathering data from machines and equipment.

- AI and Machine Learning: These help factories predict issues before they happen and make smarter decisions on the fly.

- Robots: Not just any robots—super-smart ones that can assemble, package, and even inspect products with precision./li>

- Big Data Analytics: Factories collect mountains of data, and analytics turn this data into actionable insights.

- AR and VR (Augmented and Virtual Reality): From employee training to troubleshooting, these tools make complex processes easier to understand.

- Cloud Computing:It keeps all the factory’s data safe and accessible, no matter where you are.

- Cybersecurity:With everything connected, security becomes a top priority to protect systems from cyber threats.

Why Smart Factories Are a Game-Changer

- Efficiency Boost: Machines that work smarter mean less downtime and quicker production.

- Better Products: Real-time monitoring ensures every product meets high-quality standards.

- Cost Savings: Catching problems early means fewer breakdowns and lower maintenance costs.

- Flexibility: Smart factories can adapt quickly to produce different products or meet sudden demand changes.

- Eco-Friendly: With optimized processes, smart factories use less energy and produce less waste.

How to Get Started with Smart Factory Tech

- Know Your Needs: Look at what’s working and what’s not in your current setup.

- Set Clear Goals: Are you aiming to cut costs, go green, or boost output?

- Start Small: Begin with a few smart technologies and scale up as you see results.

- Train Your Team: Your employees need to know how to use and manage these new tools.

- Secure Your Systems: Make cybersecurity a top priority to protect your data.

The Future is Here

Smart factories aren’t just a vision of tomorrow—they’re happening right now. They’re paving the way for more sustainable and innovative manufacturing, making businesses more competitive and adaptive to change. From creating better products to protecting the planet, smart factories are redefining what’s possible in manufacturing.

How Crescendo Worldwide Can Help

At Crescendo Worldwide, we understand the challenges and opportunities that come with adopting smart factory technologies. Whether you’re just starting or looking to upgrade, we can guide you every step of the way. Let’s work together to transform your factory into a future-ready powerhouse.

A smart factory uses advanced technology like sensors, AI, and robotics to make production faster, smarter, and more efficient.

They monitor every step of production in real-time, ensuring each product meets strict quality standards.

While the initial costs can be high, the long-term benefits—like efficiency and savings—make it worth it.

Almost any industry! Automotive, electronics, pharmaceuticals, and even food production are already seeing the benefits.

They use energy more efficiently, reduce waste, and support sustainable manufacturing practices.